Settings for sterilization time, sterilization temperature and sterilization pressure can be specified optionally.

| Specified pressure | 0.02~0.33MPa |

|---|---|

| Sterilization time | 4.5S~24S |

| Processing capability | MAX600L/h |

* Processing capability may vary depending on the sterilization time and raw material characteristics.

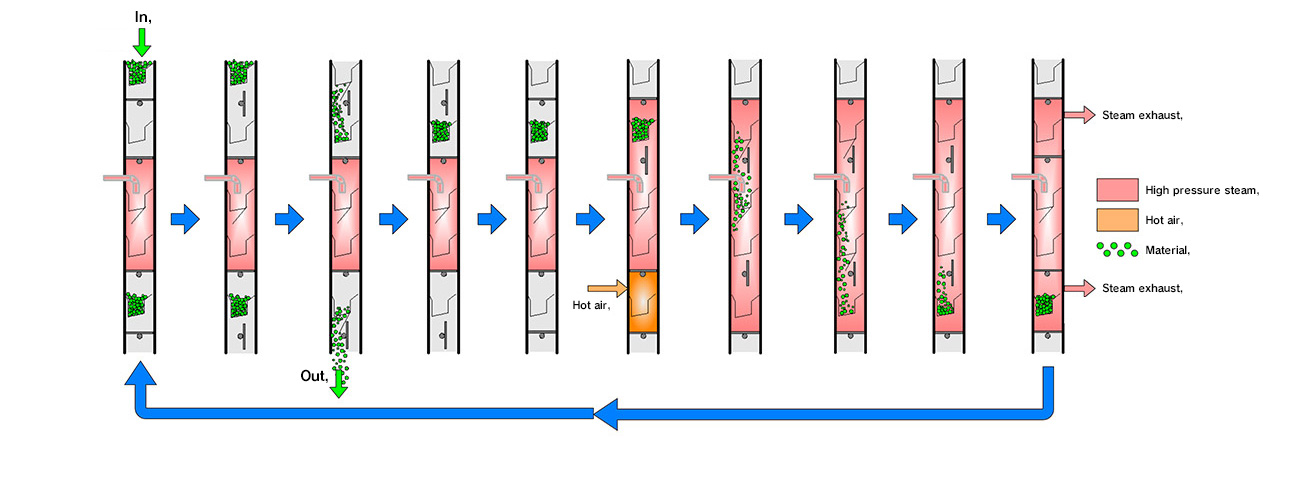

Pressured chamber is partitioned with two butterfly valves installed in both feeding and removal components, and raw materials are continuously fed into the high-pressure steam area. A straightened sterilization chamber shortens the sterilization time and improves the cleaning performance.

| Product name | Shape | General viable bacteria count | Vapor pressure (MPa) |

Sterilization time (S) |

|

| Before sterilization (CFU/g) |

After sterilization (CFU/g) |

||||

| Oolong tea | Coarse increments | 2.8×103 | Less than 300(15) | 0.20 | 5.0 |

| Jasmine tea | Leaf | 5.3×103 | Less than 300(0) | 0.15 | 4.5 |

| Black tea | Chopped | 900 | Less than 300(0) | 0.15 | 4.5 |

| Fermented Leucaena leucocephala | Chopped | 3.2×103 | Less than 300(0) | 0.30 | 7.5 |

| Black pepper | Whole | 5.5×107 | Less than 300(0) | 0.20 | 20.5 |

| Bitter gourd | Sliced | 1.2×106 | Less than 300(10) | 0.05 | 4.5 |

| Chopped laver | Chopped | 4.9×103 | Less than 300(10) | 0.10 | 4.5 |

| Shiitake mushroom | Chopped | 1.1×104 | Less than 30020(0) | 0.10 | 4.5 |

| Onion | Chip | 5.1×103 | Less than 300(0) | 0.30 | 6.0 |

| Buck wheat (peeled) | Original shape | 2.0×105 | Less than 300(0) | 0.10 | 4.5 |

| Perilla | Chopped | 1.2×103 | Less than 300(50) | 0.07 | 4.5 |

| Green dried seaweed | Chopped | 2.8×103 | Less than 300(50) | 0.10 | 4.5 |

| Turmeric | Chopped | 1.7×104 | Less than 300(0) | 0.20 | 23.0 |

| Flower | Chopped | 5.5×106 | Less than 300(0) | 0.20 | 4.5 |

| Deer-tail grass | Cut products | 1.5×105 | Less than 300(20) | 0.15 | 4.5 |

| Salad seaweed | Cut products | 50 | Less than 300(0) | 0.20 | 4.5 |

| Young barley leaf | Chopped | 1.5×107 | Less than 300(10) | 0.20 | 4.5 |

*Note that specifications and appearance are subject to change without notice in order to improve the machine.