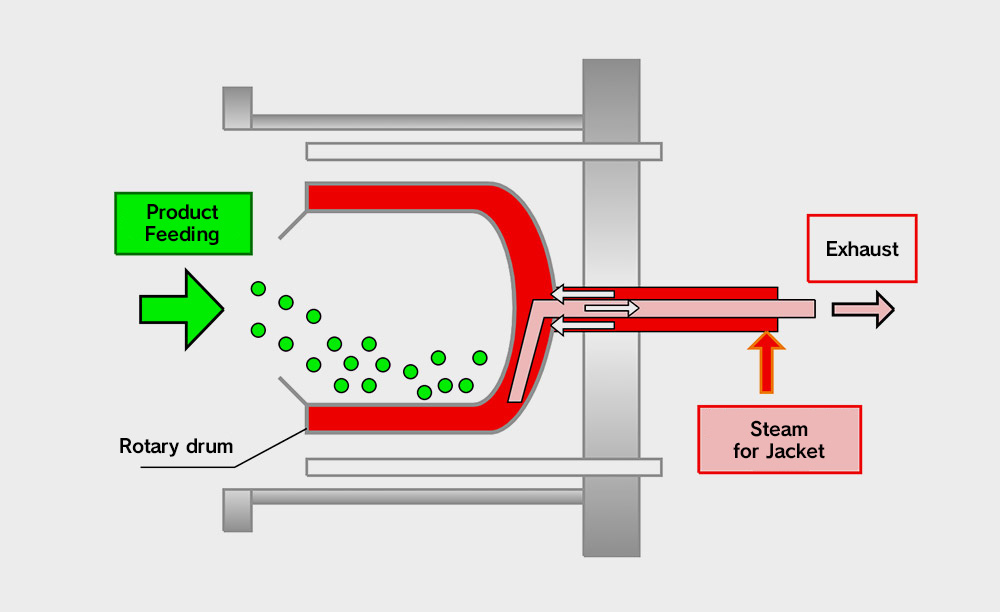

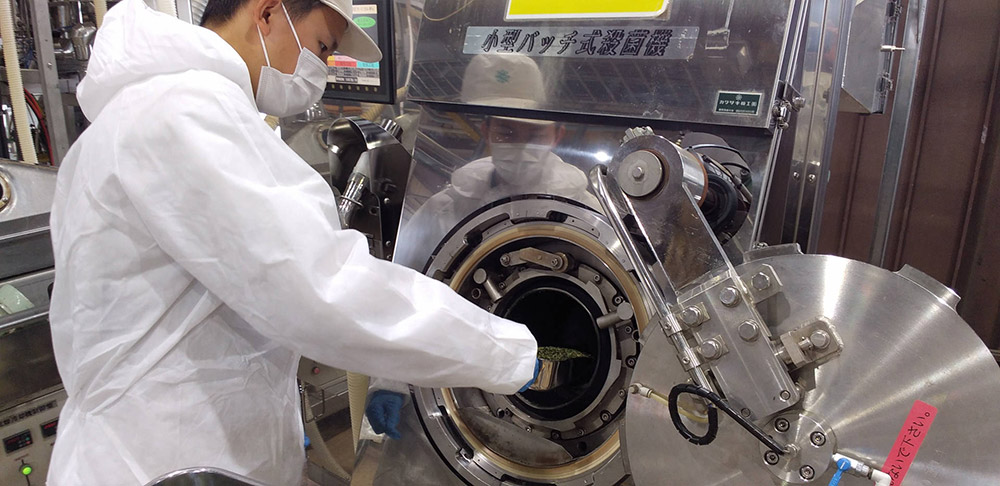

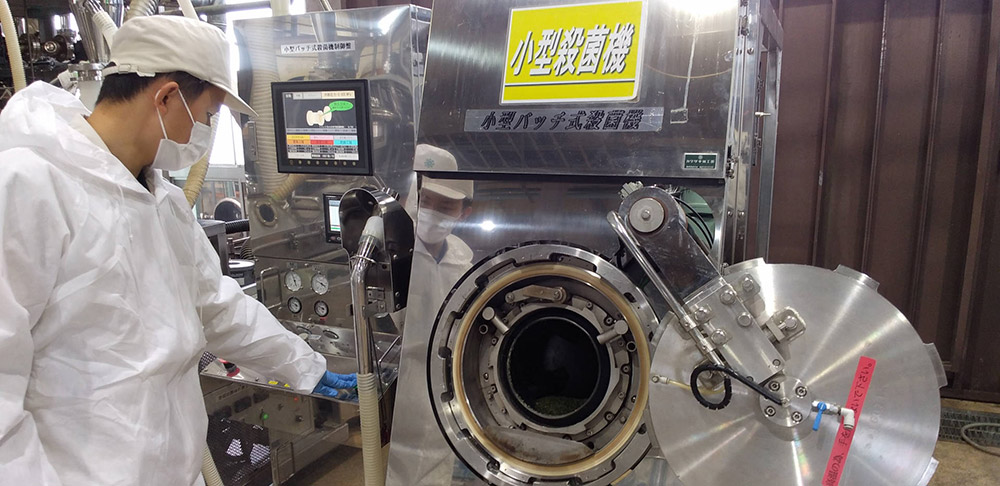

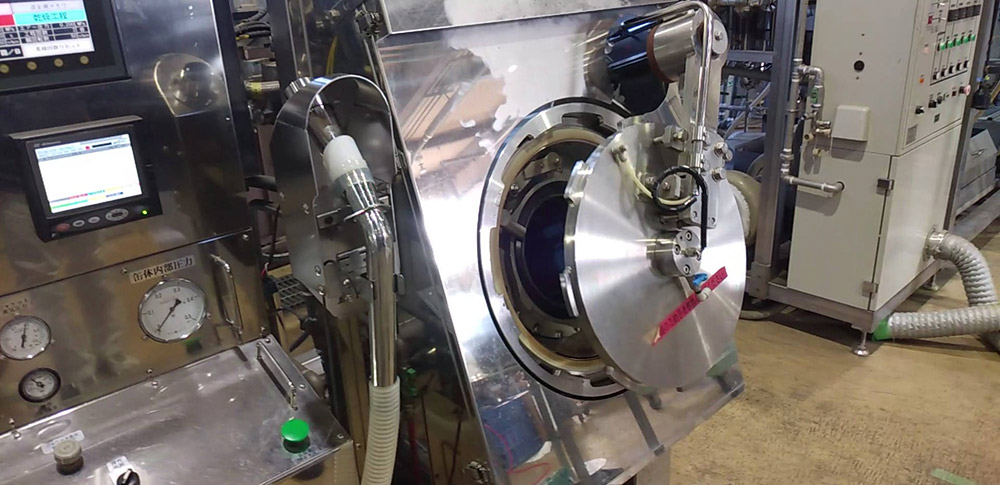

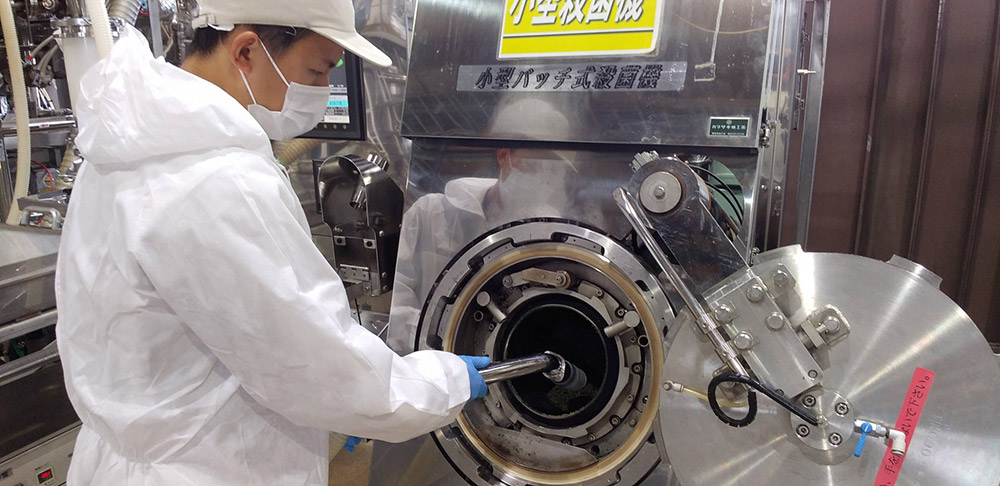

Batch type sterilizer with manual raw material feeding and removal operated by an operator.

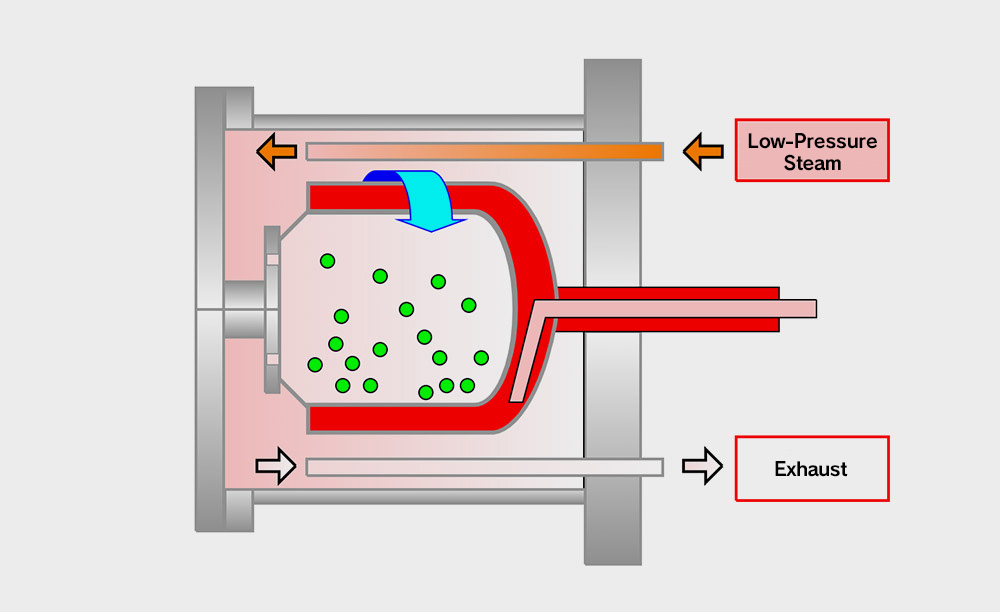

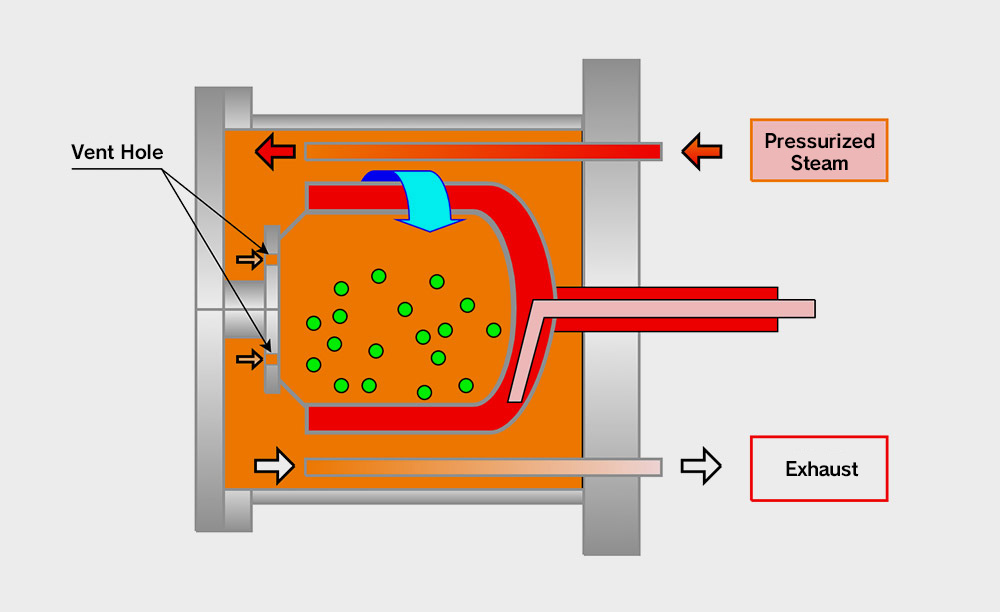

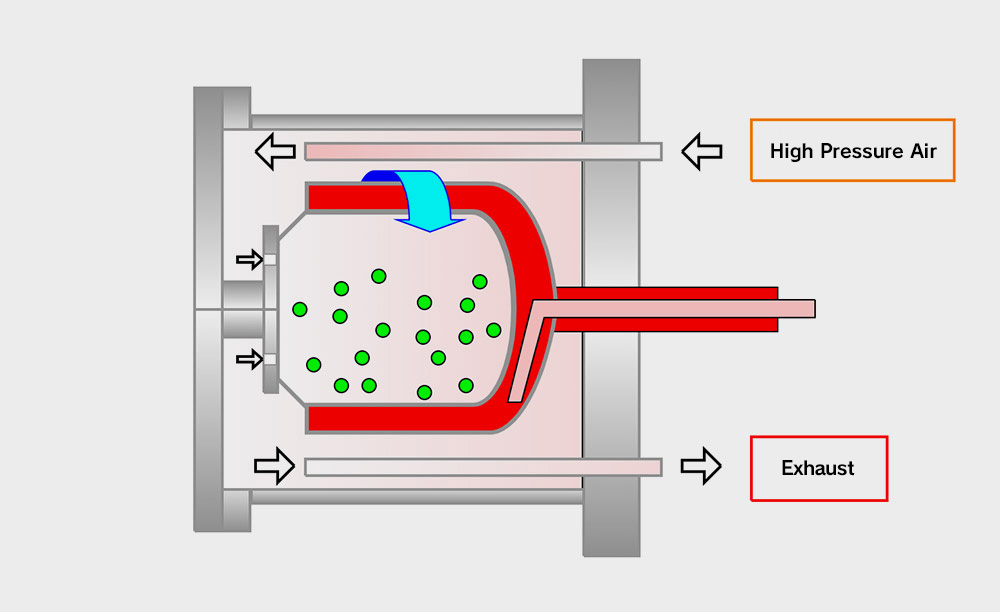

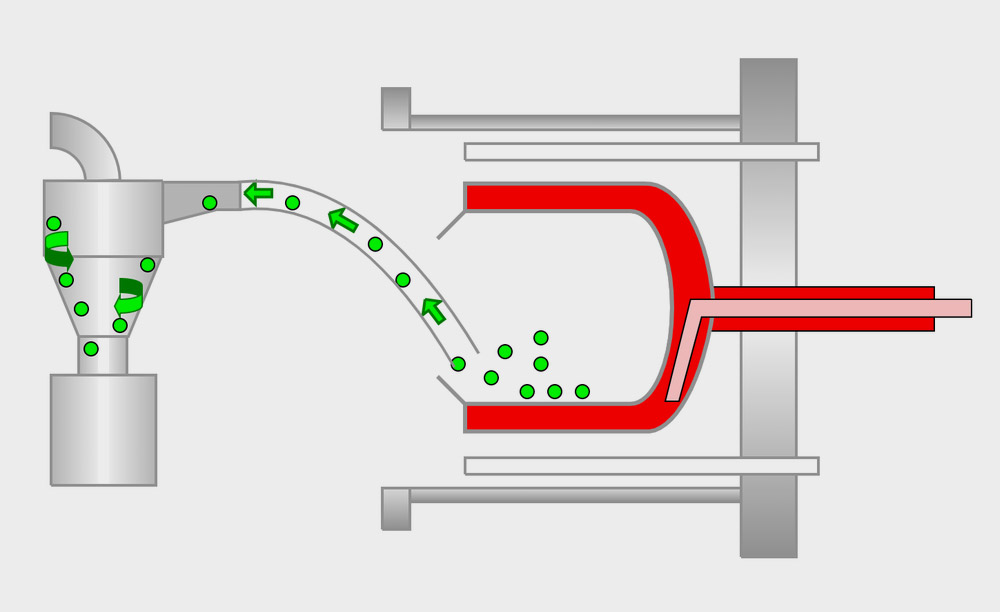

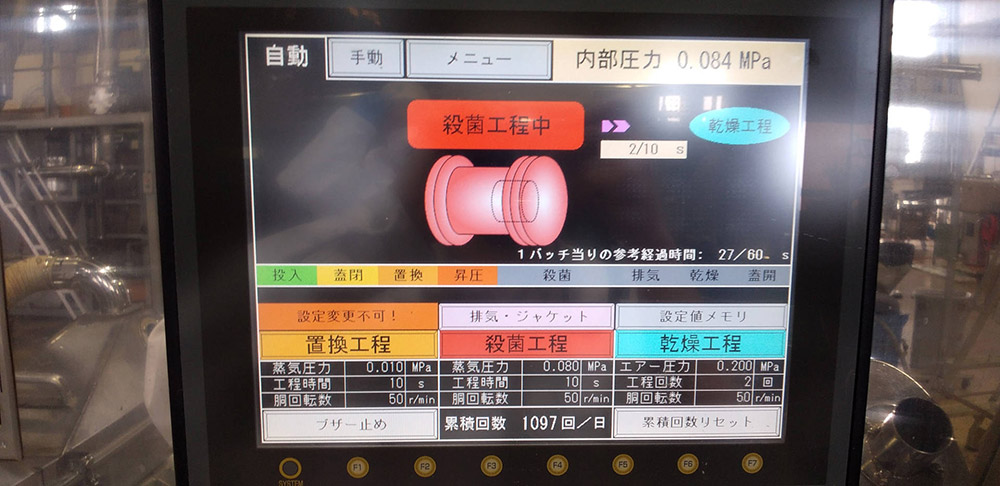

The pressurized chamber shuts out the outer air using a clutch-style auto door, and steam is supplied in the can body only when the door is closed.

The rotating drum stirring function is installed in the chamber to apply steam evenly to raw materials for stable sterilization.

Settings for sterilization time, sterilization temperature and sterilization pressure can be specified optionally.

| Specified pressure | 0.05MPa to 0.33MPa (110 degrees to 145 degrees) |

|---|---|

| Sterilization time | 0 seconds to stepless |

| Processing capability | MAX2.0L/1Batch (40kg/h:Specific gravity of an apparent case of 0.5kg/L) |

* Processing capability may vary depending on the sterilization time and raw material characteristics.

| Product name | Shape | General viable bacteria count | Specified pressure (MPa) |

Sterilization time (S) |

|

| Before sterilization (CFU/g) |

After sterilization (CFU/g) |

||||

| Licorice | Chopped | 6.4×104 | Less than 300(0) | 0.15 | 12 |

| Fennel | Whole | 3.3×105 | Less than 300(30) | 0.10 | 10 |

| Turmeric | Powder | 3.0×Larger than 106 | Less than 300(70) | 0.30 | 20 |

| Shrimp | Whole | 440 | Less than 300(0) | 0.10 | 10 |

| Canker root | Chopped | 620 | Less than 300(0) | 0.10 | 10 |

| Onion | Powder | 5.0×103 | Less than 300(0) | 0.15 | 12 |

| Onion | Sliced | 2.8×105 | Less than 300(0) | 0.15 | 12 |

| Garlic | Powder | 500 | Less than 300(0) | 0.15 | 12 |

| Garlic | Sliced | Less than 300(200) |

Less than 300(0) | 0.15 | 12 |

| Bonito | Powder | 1.7×104 | Less than 300(0) | 0.15 | 10 |

| Bonito | Chopped | 5.0×104 | Less than 300(0) | 0.15 | 10 |

| Cardamom | Whole | 1.0×104 | Less than 300(0) | 0.15 | 24 |

| Gymnema sylvestre | Chopped | 9.0×103 | Less than 300(0) | 0.15 | 10 |

| Wolfberry | Whole | 3.2×105 | Less than 300(100) | 0.20 | 5 |

| Cumin | Whole | 1.7×105 | Less than 300(0) | 0.15 | 12 |

| Cinnamon | Chopped | Less than 300(160) | Less than 300(0) | 0.10 | 10 |

| Bitter gourd | Chopped | 1.3×104 | Less than 300(0) | 0.05 | 10 |

| Bitter gourd | Sliced | 1.9×103 | Less than 300(10) | 0.05 | 10 |

| Coriander(L) | Whole | 3.0×105 | Less than 300(0) | 0.15 | 12 |

| Coriander | Whole | 760 | Less than 300(0) | 0.15 | 12 |

| Jasmine tea | Chopped | 500 | Less than 300(0) | 0.15 | 10 |

| Ginger | Chopped | Less than 300(50) | Less than 300(0) | 0.10 | 10 |

| Ginger | Powder | 1.6×105 | Less than 300(10) | 0.20 | 12 |

| Buckwheat | Whole | 1.7×104 | Less than 300(0) | 0.15 | 12 |

| Buckwheat | Powder | 3.6×103 | Less than 300(0) | 0.10 | 12 |

| Buckwheat | Whole | 3.0×Larger than106 | Less than 300(0) | 0.15 | 20 |

| Sun-dried tangerine peel | Chopped | Less than 300(20) | Less than 300(0) | 0.15 | 12 |

| Chili pepper | Powder | 2.8×105 | Less than 300(10) | 0.10 | 15 |

| Chili pepper (string shape) |

String shape | 850 | Less than 300(10) | 0.10 | 5 |

| Jujube | Chopped | 1.2×103 | Less than 300(0) | 0.15 | 12 |

| Dried small sardine | Chopped | Less than 300(50) | Less than 300(10) | 0.15 | 10 |

| Paprika (Red rose) |

Powder | 4.1×105 | Less than 300(50) | 0.15 | 12 |

| Fennel | Whole | 1.1×105 | Less than 300(0) | 0.15 | 12 |

| Pine needle | Chopped | 3.5×103 | Less than 300(0) | 0.15 | 12 |

| Fenugreek | Chopped | 420 | Less than 300(0) | 0.15 | 12 |

| Coix seed | Whole | Less than 300(270) | Less than 300(0) | 0.30 | 20 |

| Rose hip | Chopped | Less than 300(130) | Less than 300(0) | 0.15 | 12 |

| Black pepper | Whole | 3.0×Larger than 106 | Less than 300(0) | 0.30 | 20 |

| White pepper | Whole | 1.3×103 | Less than 300(0) | 0.30 | 10 |

*Note that specifications and appearance are subject to change without notice in order to improve the machine.